An aspect that shouldn’t be overlooked is that having the application as an open source release means that you can put some development skills to use and create custom features for QCAD or enhance existing ones. The panels can be repositioned and grouped in such a way that eases access and improves your workflow. In the traditional style of computer aided drafting software, all the tools that you need to create your schematics are placed in panels all around the actual drawing space. QCAD displays a graphic user interface which is more than comprehensive. So perhaps I should swap to a different footprint or design that too but I am happy with the results for this board.QCAD is an open source CAD application created to offer you the tools needed to draw two dimensional building blueprints, schematics for mechanical parts, complex diagrams and much more. I notice that my crystal sticks beyond the outline marked on the board so it is a good thing that I did not put any other components too close. The purpose of the 3D viewer is to check that your components don’t clash with each other. The decal did not get brought through but the material colours did. The footprint was saved and the 3D view automatically refreshed to show the new model.

I expect that you would be able to design in these rotations and offsets to avoid this step. Note that you need to highlight the file first before you can position it.

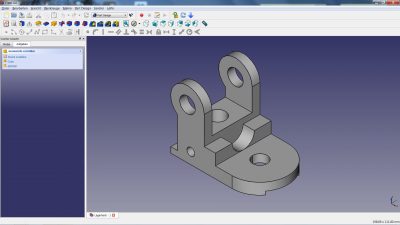

This needed a bit of rotation and positioning to align it with the PCB in the preview. In the 3D settings, I browsed to my Step file and loaded it in. Over in the PCB editor for KiCad, I found the crystal and entered the footprint editor and the footprint properties. Note that the PCB needed to be removed before I exported the model as a “STEP” format file.įrom the main KiCad screen I located the 3D models folder and copied in my file, renaming it to Crystal_AB38T_D3.0mm_L8.0mm_Horizontal.step to match the convention used by the the other files. And thanks to Pete Lomas for spotting that the end of the can needed some insulation.įinally, I added a simple PCB model with the correct hole spacing to check my model. Just for fun, I added a decal with the frequency. I assigned an aluminium material for the body and copper for the legs. The pins were extended using the pull command. I move the pins so they were 1.8mm apart then rotated them back so they pointed at the body. The sweep command combines those with the sketched line to form the bent pins.īecause the pins were 1.8mm apart I then needed to do some tuning. Next was to sketch a couple of 0.3mm diameter circles onto the end of the crystal. On this, I sketched the bent line that the pins needed to follow. To create the legs I first added a tangent plane alongside the cylinder. I added a small chamfer on the ends to make it look a bit nicer.

Over in Fusion, I started with a simple cylinder, 3mm diameter and 8mm long. I started by measuring the key parts, I also measured the pad separation which was 1.9mm between centres. But I thought it might be more fun to build one from scratch. It is often possible to find the engineering models and drawings for components and in fact I found the crystal on Digikey. I’m using 5.1 so it’s slightly different but nothing that caused me an issue.

0 kommentar(er)

0 kommentar(er)